Method in the Moulding

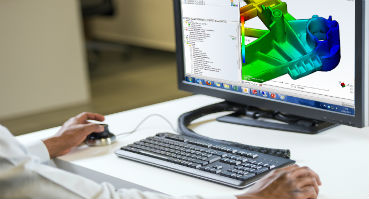

Using a systematic and methodical approach to new product development in injection moulding can help bring your products to market effectively – reducing development time, avoiding costly tooling modifications and improving part quality.

At Merit Plastics we use a thorough and time-tested approach to your project with real benefits at each stage.

- Save on costly tooling modifications and improve part quality by getting your design optimised early in development

- Reduce complexity, time and cost from your new developments with a structured AQP process

- Achieve consistent quality, low PPMs and reduced manufacturing costs with a controlled and repeatable moulding process

If you’d like to know more about the benefits our systematic approach to injection moulding can bring, get in touch on (0)1379 644 321.

Strengthen Your Supply Chain +

Improve Your NPD +

Achieve Consistent Quality +

" Merit were able to supply rapid development prototypes for me to use. I am very pleased with the whole process and would recommend Merit to anyone who needs a fast and friendly service."

Derek Killaspy, Director, Fireworks

Brochure Download

+

ISO9001 Certificate +

Plant List +

Download Full Brochure