Precision Injection Moulding From Design to Delivery

Technical Expertise : It’s what sets us apart from our competitors

Over the years, we’ve helped many companies get their products to market successfully by:

- Optimising their product designs for injection moulding

- Making ‘right first time’ tooling an achievable goal

- Developing a moulding process that ensures consistent quality

Optimising your product design for injection moulding

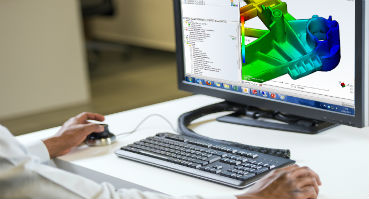

Using mouldflow simulation we evaluate your product design and make

recommendations to optimise it for injection moulding early in the development phase and before expensive tooling decisions are made

Advance Quality Planning – Getting it right first time

We use an exhaustive advance quality planning and development process to ensure a smooth transition from development to production. Comprising a review of the product design, tooling construction, materials selection, quality requirements, trials, and packaging details, this process makes ‘right first time’ tooling an achievable goal.

Achieve process capability in production

Once tooling has been manufactured, we optimise the moulding process by varying key parameters to identify the optimal settings within which the agreed part quality can be achieved. These settings are then validated using our statistical capability study, giving us and our customers confidence that the moulding process is optimised and able to produce parts consistently within specification

Strengthen Your Supply Chain +

Improve Your NPD +

Achieve Consistent Quality +